מפעל צינורות אוגן עוגן

נתוני מוצר

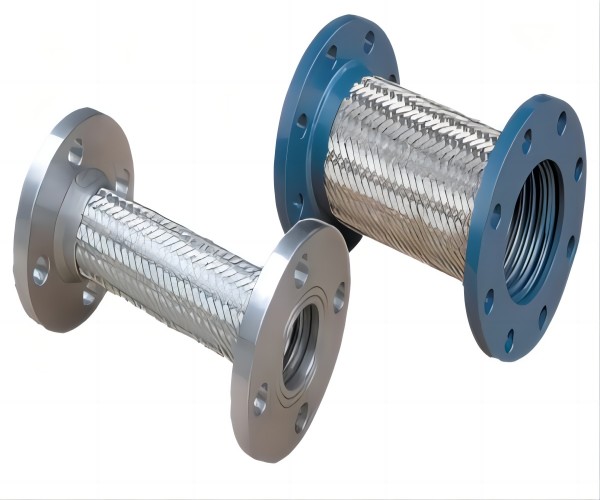

| אוגן עוגן מזויף | |||||||||

| גוֹדֶל: | 1/2"-60" DN15-DN1800 | ||||||||

| דירוג לחץ: | Class150#-2500# | ||||||||

| תֶקֶן: | ANSI/ASME או לפי בקשת הלקוח. | ||||||||

| חוֹמֶר: | פלדת פחמן, נירוסטה, פלדת סגסוגת. | ||||||||

| דרגת פלדה: | ASTM A105, A350 LF1, A350LF2, A350LF3, ASTM A182 F304, F304L, F316, F316L, F321, A694 F42, F46, F50, F56, F60, D70 וכו'. | ||||||||

| סִיוּם: | משומן או לפי דרישות הלקוח. | ||||||||

| בַּקָשָׁה: | תעשיית הנפט, חברת זיקוק, תעשיית דשנים, תחנת כוח, בניית ספינות, פלטפורמה יבשתית | ||||||||

| אוגן העוגן הוא מפחית שילוב מקשה אחת ואוגן צוואר ריתוך שתוכנן במפורש להגדלת צינורות בחיבורי אוגן למשאבות, שסתומים, מדחסים וציוד אחר. הוא מספק אמצעי קומפקטי יותר, יעיל יותר ולעיתים קרובות יותר חסכוני ממה שמתיר השילוב הקונבנציונלי של שני חלקים של מפחית קונצנטרי ואוגן צוואר ריתוך. | |||||||||

| אוגני עוגן משמשים לריסון תנועת צינור הנגרמת כתוצאה משינויי התפשטות תרמית או כוחות חיצוניים. השיטה הנפוצה ביותר לאבטחת אוגן עוגן היא להטביע אותו בגוש דחף בטון, ובכך לפזר את כוחות הצינור על פני בסיס גדול. עם זאת, ניתן לאבטח אוגני עוגן בדרכים אחרות לפי הצורך כדי להתגבר על הכוח הצירי בצינור. | |||||||||

תֵאוּר

הכירו את Anchor Flange, מוצר באיכות גבוהה שנועד לעמוד בדרישות התובעניות של מערכות צנרת תעשייתיות. מוצר זה מיוצר על ידי החברה המפורסמת שלנו הממוקמת בלב המרכז התעשייתי של העיר קנגג'ואו, מחוז הביי, מה שמוכיח את המחויבות שלנו למצוינות ולהנדסה מדויקת.

אוגני עוגן מיוצרים מפלדת אל חלד איכותית, כולל דגמים 304, 316 ו-316L, המבטיחים עמידות יוצאת דופן ועמידות בפני קורוזיה. מוצר זה תואם לתקני ASME B16.5 וזמין במספר מפרטים מ-NPS 1/2 עד NPS 24 ו-DN15 עד DN600, שיכולים לענות על צורכי צנרת שונים. רמת הלחץ של אוגן העוגן נעה בין Class150# ל-2500#, המתאים ליישומים תעשייתיים שונים ומספק חיבורים אמינים ובטוחים.

אחד היתרונות המרכזיים שלנואוגני עוגןהוא דפוס החיבור המרותך שלהם, המבטיח חיבורים חזקים וללא דליפות, ובכך משפר את השלמות הכוללת של מערכת הצנרת שלך. תכונה זו, בשילוב עם הנדסה מדויקת וחומרים איכותיים, הופכת את אוגני העוגן לבחירה הראשונה עבור יישומים קריטיים שבהם הבטיחות והביצועים הם קריטיים.

מידות ודירוגי לחץ

ASME B16.5 נירוסטהאוגן עוגן הגדלים הם 1/2 אינץ'-60 אינץ' DN15-DN1800.

רמות הלחץ בדרך כלל תואמות לתקן ASME B16.5, כולל 150#, 300#, 600# וכו'.

תכונה

1. חומרים מעולים: אוגני העוגן שלנו עשויים מפלדת אל חלד איכותית, כולל דגמים 304, 316 ו-316L. זה מבטיח עמידות מצוינת בפני קורוזיה, מה שהופך אותו מתאים לשימוש במגוון של סביבות תעשייתיות.

2. עומדים בתקנים: צינורות אוגן העוגן שלנו עומדים בתקן ASME B16.5 ועומדים בדרישות מחמירות, מה שמבטיח את התאימות וההחלפה שלהם עם רכיבים אחרים התואמים לתקן ASME.

3. מפרטים שונים: אנו מספקיםצינורות אוגן עוגןבגדלים שונים מ-NPS 1/2 עד NPS 24 (DN15 עד DN600) כדי לענות על צורכי הצינורות השונים של תעשיות שונות.

4. דרגת לחץ: דרגת הלחץ של צינורות אוגן העוגן שלנו נעה בין 150# ל-2500#, מה שמבטיח התאמה ליישומי לחץ נמוך וגבוה כאחד.

5. חיבור בטוח: צינורות אוגן העוגן שלנו משתמשים בחיבורים מרותכים כדי לספק חיבור בטוח וחזק התורם לשלמות הכללית של מערכת הצנרת.

יִתרוֹן

אחד היתרונות המרכזיים של אוגני העוגן שלנו הוא דפוס החיבור המרותך שלהם, המבטיח חיבורים חזקים וללא דליפות, ובכך משפר את השלמות הכוללת של מערכת הצנרת שלך. תכונה זו, בשילוב עם הנדסה מדויקת וחומרים איכותיים, עושהאוגני עוגןהבחירה הראשונה עבור יישומים קריטיים שבהם הבטיחות והביצועים הם קריטיים.

חִסָרוֹן

1. העלות עשויה להיות גבוהה יותר ביחס לאוגנים מסורתיים מכיוון שיש להם יכולות עיגון נוספות.

2. התקנה ותחזוקה עשויים לדרוש עבודה נוספת, כולל עיגון לקירות, רצפות או תקרות.

3. לא מתאים לכל מערכות הצנרת, מתאים רק במקום בו נדרשת תמיכה ועיגון נוספים.

שאלות נפוצות

ש 1: מהו אוגן עוגן?

אוגן עוגן הוא סוג מיוחד של אוגן שנועד לעמוד בפני כוחות צירים. הוא משמש בדרך כלל במערכות צנרת שבהן עשויה להתרחש התפשטות או התכווצות תרמית. אוגני עוגן מרותכים לצינור בנקודות קבועות, מספקים יציבות ומונעים תנועה צירית.

ש 2: תקנים וחומרים?

אוגני העוגן שלנו מיוצרים לפי תקני ASME B16.5 כדי להבטיח עמידה בתקנות ובתקנים בתעשייה. אנו מציעים אוגני עוגן במגוון חומרים, לרבות נירוסטה 304, 316 ו-316L, המספקים עמידות מצוינת בפני קורוזיה ועמידות למגוון יישומים.

ש 3: מפרטים ורמות לחץ?

אוגני העוגן שלנו זמינים במגוון גדלים, מ-NPS 1/2 עד NPS 24 (DN15 עד DN600), כדי לעמוד בדרישות צנרת שונות. לאוגני העוגן שלנו יש דירוגי לחץ הנעים בין Class 150# ל-2500#, המתאימים לסביבות לחץ גבוה וטמפרטורה גבוהה ומספקים ביצועים אמינים בתנאים קשים.

ש 4: שיטת חיבור?

שיטת החיבור של אוגני העוגן שלנו היא ריתוך כדי להבטיח חיבור חזק וללא נזילות. ריתוך מספק חיבור חזק וקבוע, שהוא קריטי ביישומים קריטיים שבהם שלמות ובטיחות הם קריטיים.

1. שקית כיווץ -> 2. קופסה קטנה -> 3. קרטון -> 4. מארז דיקט חזק

אחד מהמחסנים שלנו

טְעִינָה

אריזה ומשלוח

1. מפעל מקצועי.

2. הזמנות ניסיון מקובלות.

3. שירות לוגיסטי גמיש ונוח.

4. מחיר תחרותי.

5.100% בדיקה, הבטחת התכונות המכניות

6. בדיקות מקצועיות.

1. אנחנו יכולים להבטיח את החומר הטוב ביותר על פי הצעת מחיר קשורה.

2. בדיקה מתבצעת על כל התאמה לפני הלידה.

3. כל החבילות מותאמות למשלוח.

4. ההרכב הכימי של החומר תואם לתקן הבינלאומי ולתקן הסביבה.

א) איך אני יכול לקבל פרטים נוספים על המוצרים שלך?

אתה יכול לשלוח מייל לכתובת המייל שלנו. אנו נספק קטלוג ותמונות של המוצרים שלנו לעיונך. אנו יכולים גם לספק אביזרי צנרת, בורג ואום, אטמים וכו'. אנו שואפים להיות ספק פתרונות צנרת שלך.

ב) איך אני יכול לקבל כמה דוגמאות?

אם אתה צריך, אנו נציע לך דוגמאות בחינם, אך לקוחות חדשים צפויים לשלם תשלום אקספרס.

ג) האם אתה מספק חלקים מותאמים אישית?

כן, אתה יכול לתת לנו שרטוטים ואנחנו נייצר בהתאם.

ד) לאיזו מדינה סיפקת את המוצרים שלך?

סיפקנו לתאילנד, סין טייוואן, וייטנאם, הודו, דרום אפריקה, סודן, פרו, ברזיל, טרינידד וטובגו, כווית, קטאר, סרי לנקה, פקיסטן, רומניה, צרפת, ספרד, גרמניה, בלגיה, אוקראינה וכו' (איורים כאן כוללים רק את הלקוחות שלנו ב-5 השנים האחרונות).

ה) אני לא יכול לראות את הסחורה או לגעת בסחורה, כיצד אוכל להתמודד עם הסיכון הכרוך בכך?

מערכת ניהול האיכות שלנו תואמת את הדרישה של ISO 9001:2015 מאומתת על ידי DNV. אנחנו בהחלט שווים את האמון שלך. אנו יכולים לקבל צו משפט כדי לשפר את האמון ההדדי.

קטגוריות מוצרים

-

טֵלֵפוֹן

-

אֶלֶקטרוֹנִי

-

וואטסאפ

-

רֹאשׁ